Numerically controlled machine tool (NC machine)

CNC machine tool : Definition, operation and benefits

In the industrial sector, the demands for precision, performance and competitiveness have never been higher. CNC machine are at the heart of today'smachining and bar-turning workshops, where they enable complex parts to be produced rapidly and with great precision. At SAMO, a specialist in the sale and rebuilding of used machine tools, we help manufacturers to modernise their machinery with reliable, robust solutions tailored to the demands of the field.What is a Computer numerical control (CNC) Machine ?

An CNC machine is a machine controlled by a computer system capable of interpreting a machining programme and automatically linking mechanical operations (turning, milling, drilling, etc.). Unlike conventional machine tools, it is not guided manually by an operator, but precisely follows the instructions of a numerical programme.CNC machines include equipment such as CNC lathes and CNC machining centres. These machines offer many benefits: automation, repeatability, time savings and, above all, consistent quality on large production runs.

How does a numerical control work?

The principle of CNC (Computer Numerical Control) is based on the use of an electronic controller that controls the movements of the machine by following an instruction file. These instructions are generated from an ISO program, often in G-code language, and then interpreted line by line.

A CNC is made up of several major technical components:

- CNC control unit: the real brain of the machine, it receives and executes the digital instructions.

- Drive systems and sensors: stepper motors or servomotors move the linear or rotary axes, assisted by sensors to ensure precision movements.

- HMI and control panel: man-machine interface enabling the operator to control the machine, load programmes or adjust certain parameters in real time.

The typical machining cycle follows these steps: instructions are received, read and interpreted by the controller, coordinated movements of the axes, then machining is carried out according to the defined parameters (feed rate, depth, spindle speed, etc.).

What is CNC programming?

NC programming is the process of writing the machining programme that the NC machine will follow. There are two main approaches:- Manual programming (ISO code / G-code) allows a programmer to directly write the lines of code defining each stage of the cycle. This type of programming is used for simple parts or when flexibility is essential.

- CAM (Computer Aided Manufacturing) automatically generates the programme from a 3D model. The software establishes the optimum tool path, reduces collisions and optimises cycle times.

What are the advantages of NC machines for industry?

Numerically controlled machine tools offer many advantages for production and industrial managers:

Micrometric precision on long production runs, significant reduction in scrap and non-conformity. Tight tolerances are maintained thanks to repeatability.

Greater flexibility for series changes, with reduced set-up times. Adapted programming means you can meet demand for both small and large production runs.

Optimised productivity, with faster cycles, less human intervention, and possible integration into automated lines or robotised cells.

Industry 4.0 compatibility: connectivity, supervision, telemetry, predictive maintenance, etc. Modern NC Machines can be integrated into MES and ERP systems for global factory management.

Buying a used CNC Machine : a high-performance, cost-effective solution

For many companies, investing in a second-hand machine tool is a rational and sustainable strategy. By opting for a machine rebuilt or retrofitted by SAMO, you gain access to high-quality industrial equipment at an optimised cost.

Buying second-hand means a lower investment, rapid availability and compliance with safety and quality standards. A rebuilt and well-maintained machine offers the same performance as a new one.

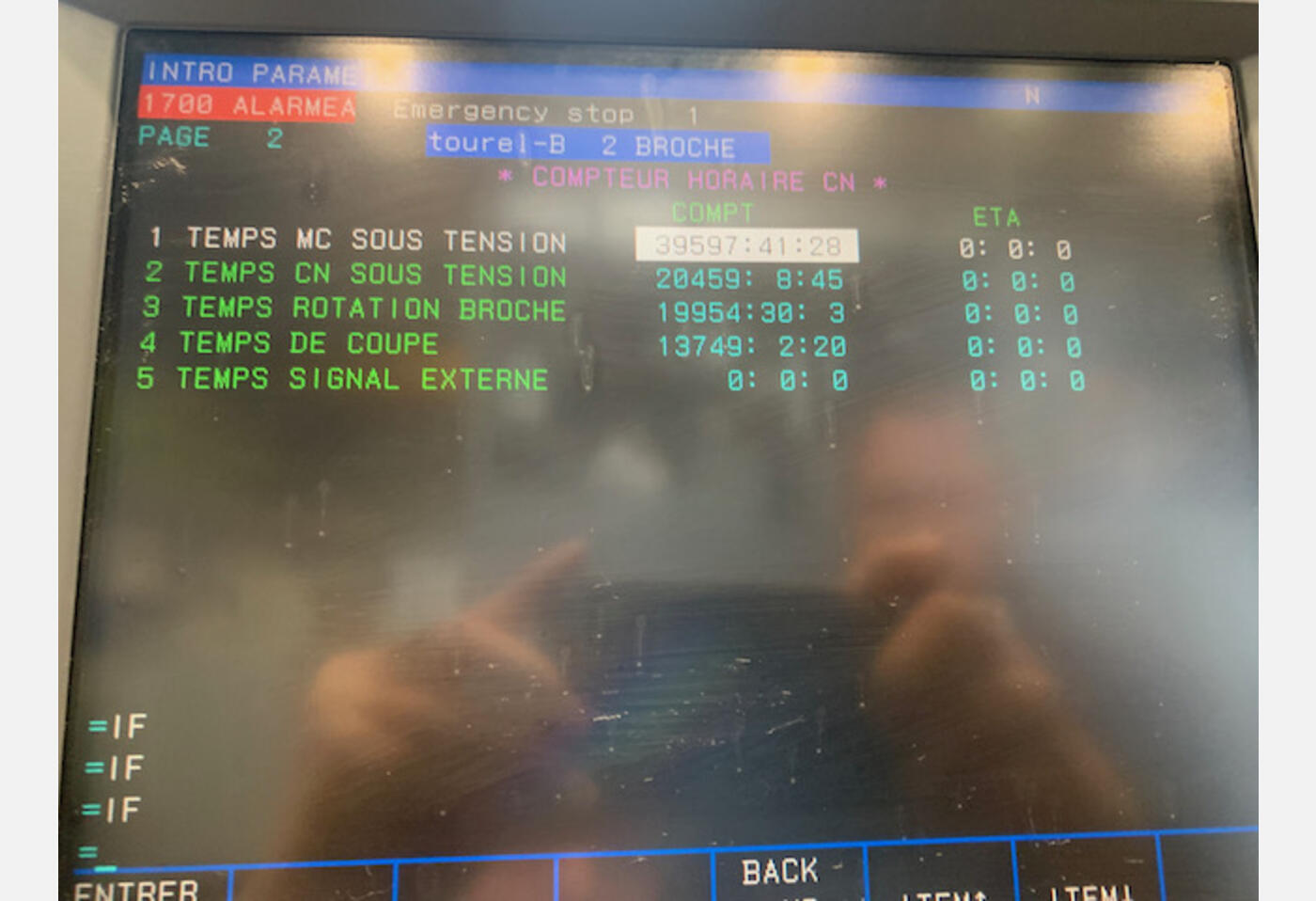

Before any purchase, it is important to analyse the general condition of the machine, its maintenance history, its number of hours, and its compatibility with your CAM tools or production systems.

SAMO will support you from selection to delivery, including on-site commissioning and training of your teams. Our technical expertise also enables us to offer spare parts for TORNOS and WICKMAN multispindle lathes, centreless grinding machines, etc.

Conclusion

The numerically controlled machine tool is a fundamental pillar of industry, along with precision, automation and performance. Understanding how it works and how it can be programmed is essential if you are to make the most of its capabilities.

When you choose a used CNC machine reconditioned by SAMO, you are opting for reliability, local know-how and long-term industrial performance. Contact us to discuss your modernisation projects or to visit our equipment available for sale.